The Integration of HIL Testing in Active Automotive Suspension Systems

Case Study

Industry: Automotive

Application: Hardware-in-the-loop (HIL) Testing

The Challenge

The Challenge

Simultaneously testing up to four active suspension electronic control units (ECUs) using a mix of real hardware components, control software, and simulated models.

Background

Background

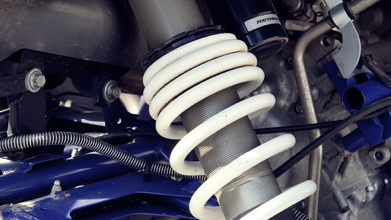

Because cutting-edge technology is constantly being introduced in the automotive industry, it can be challenging not only to design but also to test groundbreaking innovations. Our client, known for providing premium active suspension ECUs for luxury vehicles, encountered the task of ensuring seamless communication and decision-making among four ECUs positioned at distinct corners of the vehicle.

They deemed conventional closed-box testers unsuitable due to their rigid nature and potential difficulties in accommodating future functionalities. So, they began exploring a more open, adaptable solution.

The client sought a solution capable of not only simulating ECUs and sensor data but also seamlessly integrating with dynamometer test cells. Balancing the need for customization with the need to expedite product launches prompted the quest for a new approach that could effectively adapt to evolving demands of the automotive landscape moving forward.

The Solution

The Solution

Creating an open, flexible Hardware-in-the-Loop (HIL) test system based on the National Instruments (NI) technology platform that’s capable of simulating ECUs and sensor data, as well as integrating with dynamometer test cells.

The automotive client needed a customizable, high-performance HIL system capable of testing a complex active suspension system using four synchronized ECUs.

Integrating HIL and Physical Test for ECUs

Embracing the Automotive HIL Reference Design, a collaboration with Cummins and NI, and in close collaboration with the client, Genuen developed a full-height HIL system that simulated vehicle sensors. The solution incorporated modular PXI hardware, NI TestStand and NI VeriStand test software, and a third-party mass interconnect. The system could model ECUs with just one available DUT or employ HIL models to simulate all four ECUs against real or simulated sensor data. This Software-in-the-Loop (SIL) scenario empowered developers to test ECU software earlier in the design cycle and reduced regression testing time.

Moreover, because of the open platform, the team achieved seamless integration with external dynamometer test cells, enabling concurrent product development and early-stage testing. By untangling dependencies between different internal groups, the solution expedited time-to-market and mitigated the risk of identifying design flaws late in the development cycle.

Based on the NI technology platform, this open, flexible HIL test system is capable of simulating ECUs and sensor data, as well as integrating with dynamometer test cells.

Collaboratively Designing a Full-Height HIL Tester

Collaboration extended beyond technical considerations. The client, seeking complete ownership and customization post-deployment, valued Genuen's involvement in the quoting and system-design process. Despite initial unfamiliarity with NI technology, they swiftly adapted, leveraging NI's training resources and support from Genuen. The integration of Python code with NI TestStand improved flexibility and automation and aligned with their internal programming expertise.

Ultimately, we delivered a full-height HIL tester capable of modeling multiple ECUs and sensors, providing valuable insights into the functionality of the overall active suspension system. This integrated testing approach empowered the client to make informed decisions early in the development cycle and resulted in a robust offering poised for customer delivery.

Related Links:

Ford Deploys Fuel Cell Test System Using INERTIATM Software

Improving Automotive Battery Management Systems Using HIL Simulation