Dynamometer Test Systems

From control upgrades, to full turn-key dyno test cells

Custom Systems

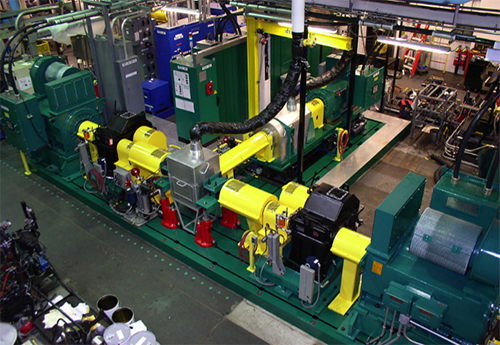

Genuen offers test cell modernizations as well as turn-key test cell installation services for systems ranging from AC motor, hydrokinetic, hydrostatic, electric AC/DC, eddy current, and hysteresis brake dynamometers.

Dynamometer Core Competencies

Gas and Diesel Engine Dyno

Transmission dyno

Electric Hybrid Motor Dyno

Transaxle

Driveline

Clutch and Brake Dyno

Powertrain

Components

Dynamometer Test Cell Examples

Learn more about our dyno test cell services by checking out these case studies.

HARDWARE

Turn-key Dynamometer Controller

The DynEDGE dyno controller is an integrated, multi-loop control and data acquisition system suitable for dynamometer applications from system upgrades to new installations. DynEDGE utilizes off-the-shelf NI PXI hardware, NI VeriStand, and Genuen’s INERTIA test software to minimize your investment while maximizing configurability.

SOFTWARE

Real-Time Control Software for Test Cells

Continuously developed for nearly 20 years, INERTIA is automation software we have developed for powering our real-time test cell designs to enable engineers to quickly configure their plant, develop test sequences, and operate the cell from a no-code, drag-and-drop interface.