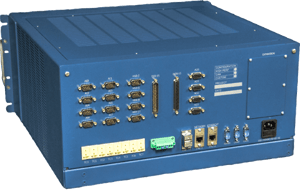

Rapid II

Multi-Loop Test Cell Control and DAQ System

Modular Test Cell Controller

Designed to combine the latest in digital control software with off-the-shelf hardware, Rapid II provides high-speed, 4-channel PID control, includes ample I/O for system control and data acquisition, and is engineered to reduce test cell complexity. Contact us to discuss whether Rapid II can enhance the capability of your test cell.

Specifications

The 19” 5U rack-mount turnkey solution is well-suited for engineers looking to replace legacy controllers, or to add features to existing systems, including:

-

Out-of-the-box functionality with quick installation and easy configuration

-

Deterministic performance and reliability provided by the power of an FPGA

-

Easy connectivity and wiring to I/O, safety circuits, and various signal conditioning options

-

Extensive software capabilities including easy, user-configurable screens, flexible control settings, test profile creation, and data logging

-

Cost-efficient, open-source solutions for multi-axis control and data acquisition

Features

Each Rapid II controller comes with standard, preconfigured I/O and a desktop computer preloaded with INERTIA™ control software. Features include:

-

4-axis test cell controller with up to 1 kHz digital PID loop closure

-

19” 5U rack-mount enclosure

-

Wide variety of preconfigured I/O including 8 analog inputs, 16 digital inputs, and 16 digital outputs

-

I/O accessible via D-Sub connectors

-

Operator desktop computer preloaded with INERTIA™ control software and examples

-

Software features extensive user configuration options with flexible control settings, test profile creation, configurable alarms, definable user interfaces, data acquisition, and reporting functions

-

Emergency stop button and connectivity to safety circuits

-

Ribbon cable connectors that provide expansion options for signal conditioning backplanes, digital I/O, TTL level I/O, and other connectivity products