Ford Deploys Fuel Cell HIL Test System Using INERTIA Software

Case Study

Industry: Automotive

Application: INERTIA, Control and Data Acquisition, NI Veristand, Electromechanical Testing

The Challenge

The Challenge

Creating a hardware-in-the-loop (HIL) test stand to simulate, control, and monitor passenger vehicle fuel cells developed by Ford Motor Company.

Background

Background

Fuel cells are electrochemical devices that convert hydrogen gas and atmospheric oxygen into electrical energy and water. Ford Motor Company is pursuing fuel cells as an alternative energy source for powering passenger vehicles. As part of their research, they needed a test stand with the ability to:

-

Simulate the vehicle inputs to the fuel cell

-

Control and monitor the system around the fuel cell as well as the fuel cell itself

-

Acquire the data for analysis

-

Adapt easily to future fuel cell prototypes

Fuel cells require precise control of the incoming resources, as well as a tight balance of temperature, flow and pressure control of the coolant. In addition to these incoming resources, the fuel cells are designed to be commanded and controlled electronically by the vehicle engine control unit (ECU) to provide the required vehicle performance dictated by the driver’s input. In the actual vehicle, the vehicle ECU typically provides the closed loop control via CAN bus signals both coming in and going out of the ECU. Finally, when new prototype fuel cells are developed, Ford’s Fuel Cell Development Team needs to be able to bring the new prototype to the stand with a different set of control parameters, a different ECU CAN database and a different set of onboard sensors to be monitored and simply adjust the configuration of the test stand through menus to quickly and easily adapt to the new fuel cell.

The Solution

The Solution

Using National Instruments (NI) VeriStand real-time test environment, Genuen (formerly WTI) INERTIA™ control software add-on, and NI PXI hardware to create a flexible, scalable solution for evaluating alternative fuel vehicle application systems.

Figure 1. Ford Motor Company needed a flexible HIL test stand for evaluating passenger vehicle fuel cells.

Building a Complete Hardware and Software Solution

As recommended by National Instruments, Ford Motor Company selected Genuen to develop a standard software solution that provides the underlining system architecture for control, data acquisition, and monitoring of the required system parameters. For an easy-to-use test software environment, NI VeriStand and the INERTIA real-time control add-on were selected for development and deployment onto the real-time platform. The hardware equipment included the integration of PXI, SCXI, R-Series modules with field programmable gate arrays (FPGA), and an EtherCAT distributed I/O device to provide a robust and modular platform for the HIL system. Using the NI VeriStand API, a custom LabVIEW application was also developed for the user interface to provide even greater flexibility and customization.

Figure 2. Genuen built a complete turnkey solution that integrated NI VeriStand, INERTIA real-time control, PXI, SCXI, R-Series modules with FPGA, and EtherCAT distributed I/O.

Developing the Real-Time Software Application

Running NI VeriStand on a real-time PXI controller quickly gave us an application that could perform deterministic control with real-time data logging. Adding the INERTIA real-time control add-on to NI VeriStand provided multi-mode PID support that allows the control of a single loop to switch between temperature, pressure, or flow mode dynamically as the system calls for it.

Using Custom Devices for greater functionality NI VeriStand opens up increased hardware and software functionality that is not part of the base application. Once created and added to NI VeriStand, these custom devices are fully integrated throughout the application with the same deterministic performance as if they were an original part of the base application. Genuen leveraged this feature to create custom devices for enhanced alarming functionality (Alarm Matrix) and the vehicle system controller (VSC) that emulates the outputs of the target ECU. Both of these custom devices perform critical functions that require real-time response to conditions.

The Alarm Matrix custom device monitors channels and the vehicle system state. Based on definable alert levels and the vehicle system state, the Alarm Matrix performs actions and mitigates system outputs from the VSC based on the specified alarm states and required alarm actions. The VSC custom device was developed as a way to simulate the engine control module of the vehicle, acting as a gateway for the fuel cell system. The VSC is responsible for accepting power and cooling requests from the fuel cell system, verifying the systems condition to provide those requested levels, and requesting the desired levels or reporting back to the fuel cell system via the CAN bus.

Interfacing with Vehicle Models

Running Genuen was also able to use NI VeriStand to easily interface with custom LabVIEW code, MATLAB models, or compiled models developed in other development environments. The particular tool that was implemented controls a peripheral electronic load over the CAN protocol. The CAN database is uploaded inside of the NI VeriStand environment and the signals are linked to the outputs of the model. When the model runs, it is able to perform real-time logic to ensure that the electronic load is in the correct state.

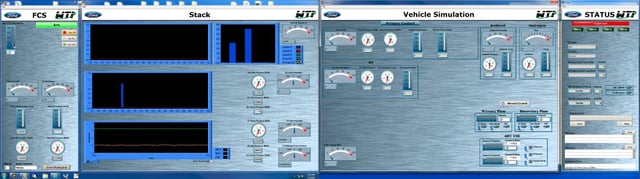

Customizing the User Interface

A custom LabVIEW application was created to dynamically spawn NI VeriStand and multiple applications VIs that provides the user with an array of tools and I/O screens. These tools and screens are programmatically set to display on demand based on the number of monitors connected to the system. These custom software screens and tools provide the user the exact customized GUI functionality and displays Ford required for the application and also include the ability to interact with NI VeriStand functions such as channel configuration, calibration, calculated channels, and test profile generation.

In the next iteration of this application, Ford has selected Dynacar™, an NI VeriStand add-on for full vehicle simulation that includes not only the ability to select the target vehicle the fuel cell will be implemented in, but also the ability to configure the simulator through drop-down menus to closely replicate the target vehicle without the need to provide complex models. By adding Dynacar to the system, the Ford Fuel Cell Development Team will be able to include the necessary hardware to include an actual driver in the loop, thus enabling the evaluation of the system in a vehicle under actual driving conditions without ever leaving the test stand.

Figure 3. A custom LabVIEW application was developed to programmatically display appropriate tools and I/O screens on demand.

Quickly Changing Out Sensors for New Fuel Cells

The sensors used with each new fuel cell will vary from prototype to prototype. Therefore, one of the requirements of the test stand was the ability to quickly accommodate these sensor changes with little effort. The feedback from these sensors is crucial to understanding the interaction of the fuel cell in conjunction with the operation of the test stand operation, and in order to understand this relationship, they must be logged and synchronized with the test stand data. Using an EtherCAT distributed I/O chassis allows the sensors to be changed and wired to the chassis independently before the fuel cell is brought into the test cell. Therefore, the test stand can still be in operation while a technician or engineer is wiring the next fuel cell to be tested, thus saving time and resources. It also allows each new fuel cell’s list of sensors to be quickly changed out by updating the EtherCAT device settings inside NI VeriStand through configuration utilities.

Consistently Delivering Complex Test Solutions

In conclusion, the Genuen project development team, working closely with the NI VeriStand development team and Ford Motor Company, delivered a system that provided an intuitive solution for a very complex alternative fuel vehicle application system. Genuen's long history of developing high-performance real-time control and data acquisition systems, our close relationship with National Instruments, and in-depth knowledge of NI’s real-time hardware and software platform has enabled us to deliver a very advanced, robust, flexible, and user friendly system that achieves all of Ford Motor Company’s test system requirements.

Thank You to Todd VanCamp at Ford Motor Company for help with this article.

Related Links:

Flexible Automotive HIL Simulation for Complex Active Suspension System

Improving Automotive Battery Management Systems Using HIL Simulation