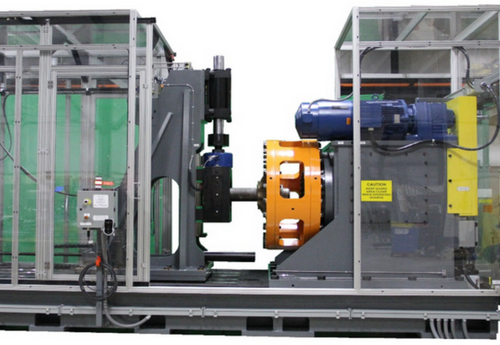

Test Platform Development

Beyond One-Size-Fits-All: Customized Collaboration for Developing Your Test Platform

Collaborative Test Platform Development

Your test and measurement projects demand specific solutions, but internal teams can get siloed when everyone is starting from scratch. Utilizing the open, productized foundations of NI VeriStand and our INERTIA™ test software, our internal LabVIEW test frameworks, and your unique perspective, we collaborate with you to create common hardware and software platforms to combat the risk of technological debt and cost overruns.

SOFTWARE

Real-Time Control Software for Test Systems

Continuously developed for nearly 20 years, INERTIA is automation software we have developed for powering real-time test cell designs to enable engineers to quickly configure their plant, develop test sequences, and operate the cell from a no-code, drag-and-drop interface.

Test Platform Development Solutions

Learn more about our test platform development services by checking out these case studies.

.png?width=400&height=400&name=2018%20Partner%20of%20the%20Year%20Americas%20(2).png)